Quality Control

Quality Control

A GRAIN SAVED IS A GRAIN PRODUCED.

INTRODUCTION:–

The practice of checking goods, products etc during and after the production process to make sure that they are of expected standard. It is a process through which it is to ensure that product quality is maintained or improved. Quality control involves testing units and determining if they are within the specifications. Quality control process assures that the product developed is of required quality.

AIMS:-

- Effective price support operations for safeguarding the interest of the farmers.

- Distribution of food grains throughout the state for Public Distribution System.

- Maintaining satisfactory level of operational & buffer stocks of food grains to ensure National Food Safety & Security Act by Food Safety and Standards Authority of India.

OBJECTIVES:–

- Enhance product quality & reduce risks.

- Improve quality of food grains.

- Fulfillment of all the targets set up as per Govt. Of India food policy norms time to time.

- Monitoring the quality in all major transactions process leading to improved consumer satisfaction level and loyalty.

- Accountability for efficiency, responsiveness, performance & minimization of all loses and wastes.

- Up gradation of infrastructure and work environment & enhancement of availability of knowledge and skills.

- Transparency in decision making, establishing, maintaining & improving ISO 9001:2000 based Quality management systems covering all areas of activities.

FOCUS:–

- Professional excellence in management of food grains.

- Transparency and accountability in transaction.

- Optimum utilization of resources.

- Continual improvement of systems, process & resources.

ODISHA STATE CIVIL SUPPLIES CORPORATION LTD.

OSCSC ltd was established on 3rd September, 1980 as a fully owned State Government Company under Companies Act, 1956.

MISSION

The Corporation maintains a no profit no loss status, in order to fulfill its commitment to serve the poor segments of the society.

VISION

OSCSC is now playing a pivotal role in implementation of the decentralized procurement operations in the state & committee to procure and distribute FAQ rice confirming to the Uniform Specification of Govt. of India under NFSA/WBNP/MDMS & other welfare scheme programme.

MANDATE

Food and nutrition are among top priorities. No one not a single person should go hungry. To satisfy the needs of consumer and to maintain good quality with Zero Hunger challenge.

QUALITY CONTROL CELL OF OSCSC LTD.

- In order to fulfill the mission a Quality Control Cell was established. We value Quality. Our endeavor is to maintain good quality of every grain we offer.

- Paddy & rice should be in sound merchantable condition , sweet , dry, clean, wholesome of good food value, uniform in colour and size of grains & free from moulds, weevils, obnoxious smell, admixture of unwholesome poisonous & deleterious substances, any coloring agents & all impurities.

- Food grains are exceeding durable and at the same time are highly perishable due to involvement of biotic factors like insects, rodents, birds & microbes and abiotic factors like moisture, temperature & relatives humidity. Preservation ensures safety of food grains during storage.

- Normal detoriation in food grains under adverse condition of storage is discoloration , sprouting , development of undesirable orour , mustiness, growth of micro –organisms, cake formation & contamination etc resulting in unfit for human consumption . These are controlled by proper aeration, ventilation & prescribed periodical chemical treatment.

- So Quality Control plays a vital role to maintain the quality standards at the time of acceptance / procurement, during storage & at the time of issue of Custom Milled Rice.

QUALITY CONTROL (TECHNICAL) WING OF OSCSC:-

- Quality Control (QC) wing is the backbone of the functioning of OSCSC, which is manned by qualified & trained personnel entrusted with enormous task of procurement & preservation of food grains.

The role of Quality Control division is very crucial of every stage including receipt, storage/preservation at depot & issue to the PDS (Public Distribution System).

-

- Quality Control personnel have to ensure the Quality of food grains strictly in accordance with Govt.of India’s Uniform Specification.

- Food grains are received and stored in OSCSC own and hired godowns where QC personnels have a vital role in preservation of food grains.

- Food grains are issued as per quality norms to State Govt. under PDS at central Issue Price fixed by Govt. Of India to fulfill the objectives of helping the economically backward sections of society.

- Food grain samples are also referred to OSCSC Head Office Quality Control laboratory on monthly basis and get tested for its conformity of parameters also leading to improved satisfaction level to the consumers.

- OSCSC appointed Quality Analysts to look after the quality aspects of food grains during receipt from custom millers, storage / preservation in godowns and at the time of issue under supply chain. He/ She has to ensure receipt of CMR strictly as per Uniform Specification at RRCs.

-

Visual Inspection of Sample: –

Rice shall be in merchantable condition, uniform in size & colour, free from musty smell & living insects. Besides common merchantability, the sample should conform to maximum limits of refractions as per the scheduled of specification.

-

Determination of Moisture content:

– Moisture shall be tested in digital moisture meter testing machine.

-

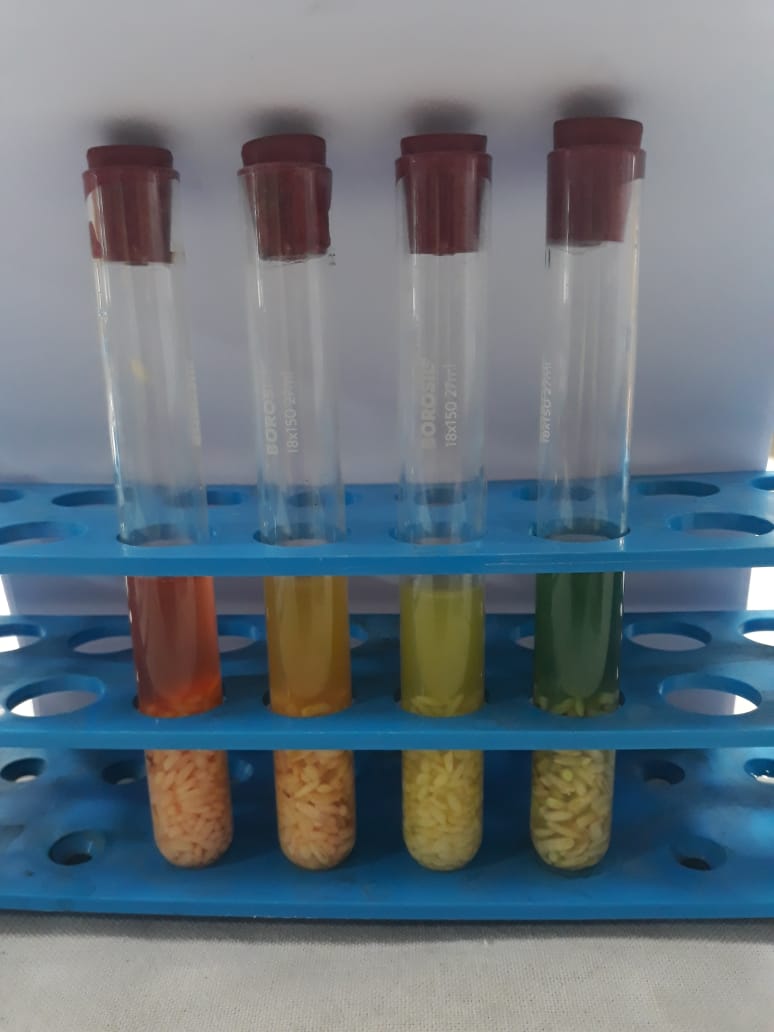

Assessment of Impurities: –

physical analysis shall be made taking test sample for determining refractions like foreign matters, damaged discolored, chalky grains, red grains & admixture of lower classes.

-

Chemical analysis : –

Acid test shall be conducted for finding dehusked grain percentage.

-

Recording of particular analysis result: –

After all tests are made the percentage shall be calculated & recorded in sample analysis register.

-

Maintaining Quality Control Registers: –

1) Stack Completion –cum- Priority register, 2) stack wise fortnightly inspection Register, 3) Spray Register,

4) Fumigation Register, 5) Stock register of chemicals & fumigants, 6) Lot rejection Register, 7) Stack wise stock register.

QUALITY CHARACTERISTICS:–

Quality characteristics of paddy and milled rice can be considered separately. A no. of interrelated features determining the Quality of food grain. These are:-

- Moisture content of paddy.

- Purity degree

- Varietal Admixture

- Cracked grain

- Immature, shrunken & shriveled grains.

- Damaged, discolored, sprouted & weevilled grains.

- Broken grains.

- Foreign matters.

- Chalky grains.

- Red grains.

- Dehusked grains.

- Fortified rice kernel.

QUALITY TESTING EQUIPMENTS :–

- Moisture meter.

- Sample divider.

- Set of shieves.

- Analysis kit with accessories.

QUALITY IS MORE IMPORTANT THAN QUANTITY.

Quality Control Responsibilities in Head Office

| Sl. No. |

Functions/Correspondence in Q.C cel |

|---|---|

| 1 | Physical Analysis and Chemical Analysis of samples sent by 30 districts in fortnightly basis as per circular no. 14473 dt.05.10.21 after proper coding followed by different procedures of Analysis. |

| 2 | Maintaining laboratory and safety equipments of Q.C cell. |